At LoongBuy, product quality is not an afterthought—it's the foundation of our promise to our customers. We understand that trust is built on consistency and reliability. To uphold this, every item that passes through our fulfillment center is subjected to a rigorous, multi-step Quality Control (QC) process. Our system is designed to scrutinize four critical aspects: Size, Color, Stitching, and Packaging. This meticulous approach ensures that only products meeting our exacting standards reach storage, and ultimately, our valued customers.

The Four Pillars of LoongBuy's QC Inspection

Our QC specialists follow a standardized checklist for every single item. Here’s a detailed breakdown of each inspection step:

1. Dimensional Accuracy & Size Check

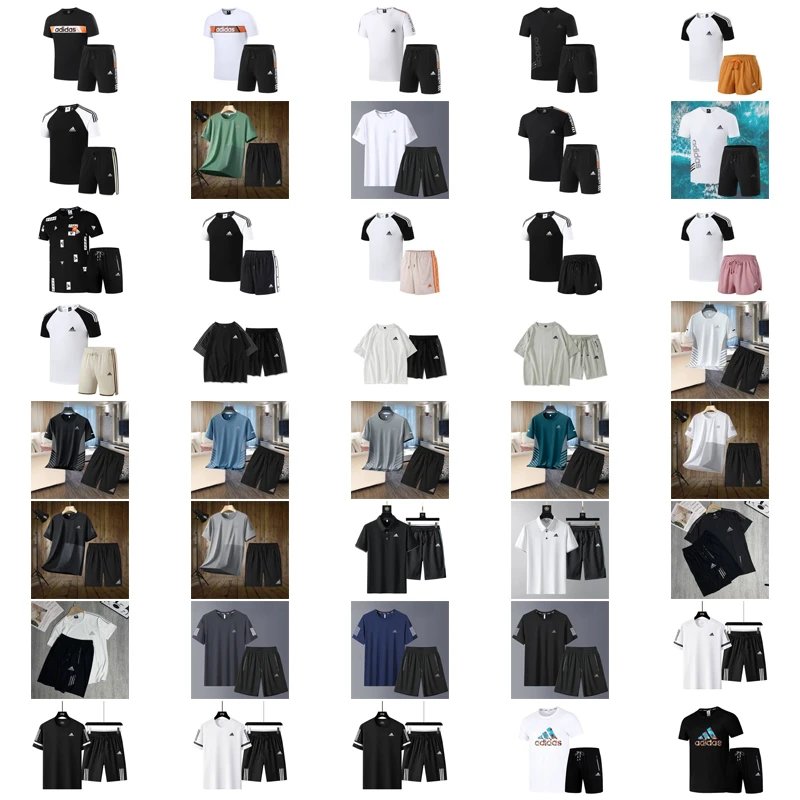

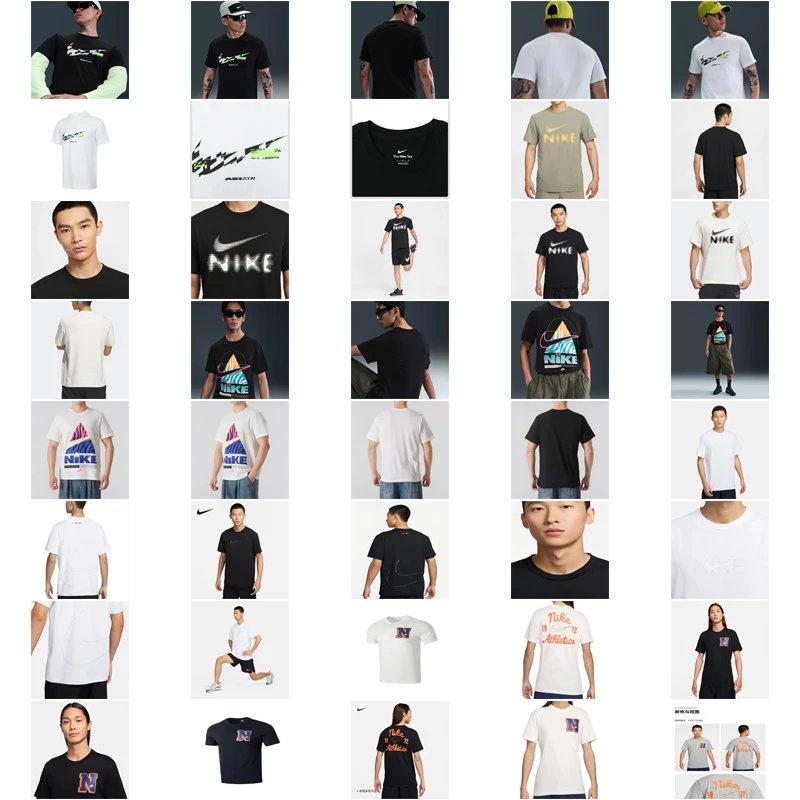

The first step verifies that the physical dimensions of the item match the product specifications listed on the website. For apparel, this includes laying the garment flat and measuring key points like chest width, sleeve length, and hem. For other products, precise tools are used to confirm length, width, and height. Any deviation beyond our strict tolerance levels results in the item being flagged for review.

2. Color & Material Consistency

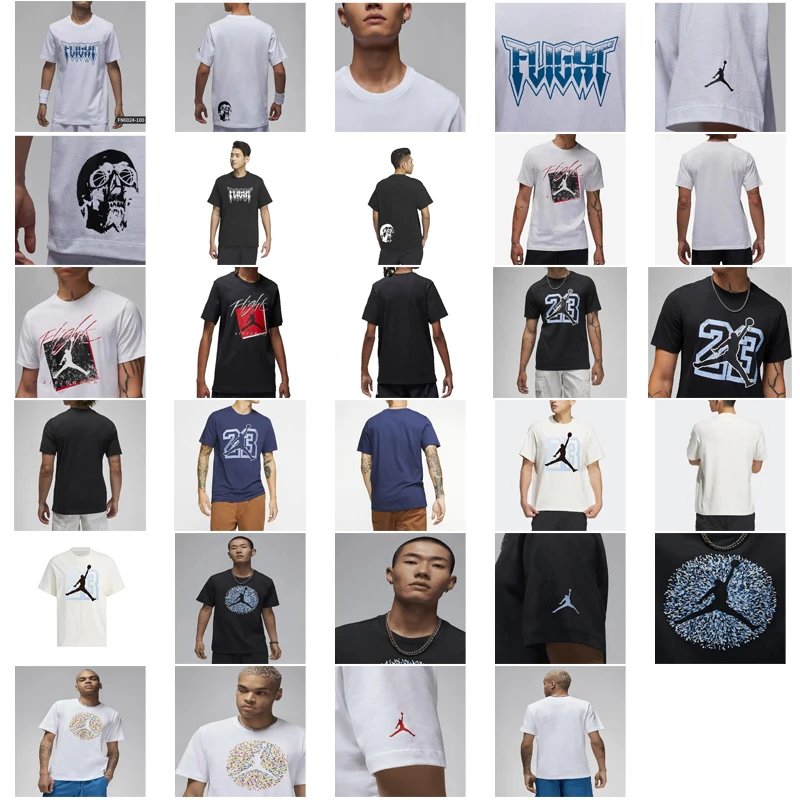

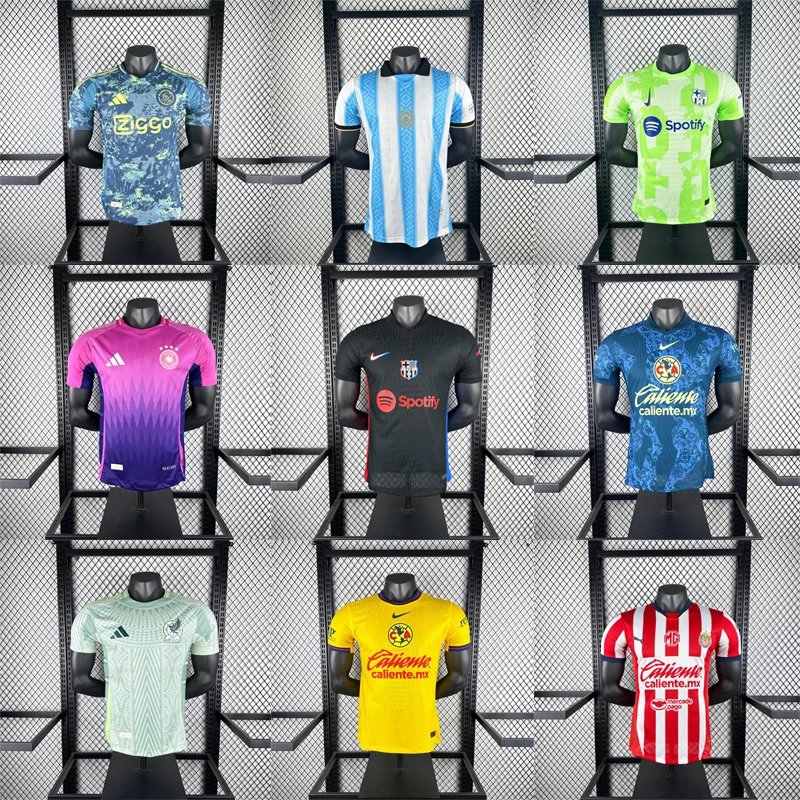

We ensure the item's color perfectly matches the approved sample and the images displayed online under calibrated lighting conditions. Our team also examines the material for quality, texture, and any imperfections such as discolorations, spots, or inconsistent dye lots. This step is crucial for maintaining brand integrity and customer satisfaction.

3. Construction & Stitching Integrity

This is a thorough examination of the product's build quality. For clothing and bags, we inspect seams for straight, secure stitching with no loose threads, skipped stitches, or weak points. Buttons, zippers, snaps, and other hardware are tested for functionality and secure attachment. For electronics or hard goods, we check the assembly for integrity and any surface defects.

4. Packaging & Presentation Audit

Before an item is cleared for storage, its packaging is carefully inspected. This includes verifying the correctness of all labels, barcodes, and price tags. The packaging itself must be pristine—free from dents, tears, or seals that are not secure. We also confirm that all included components, such as manuals, accessories, or warranty cards, are present and correct.

Ensuring Accuracy Before Storage

Following the successful completion of all four inspection stages, the item receives a final approval stamp from the QC team. It is then systematically logged into our Warehouse Management System (WMS), updating its status to "QC-Passed" and ready for storage. Items that fail any step are immediately separated and moved to a quarantine area. They are then documented with a detailed failure report, which triggers a review with our procurement and vendor teams to address the root cause.

This closed-loop process does more than just filter out defects; it provides vital data that helps us continuously improve our product sourcing and work more effectively with our manufacturing partners.

Conclusion

LoongBuy's detailed QC process is a testament to our commitment to excellence. By deconstructing quality control into these clear, actionable steps, we build a scalable system that protects our customers from receiving incorrect or substandard products. It is this unwavering attention to detail that allows you to shop with confidence, knowing every LoongBuy item has been verified for accuracy, quality, and completeness before it ever reaches your door.